Our finger joint boards are engineered for consistent strength, smooth surfaces, and optimal performance for furniture and construction.

SSR panels are crafted for clean finishes and long-term performance in furniture production.

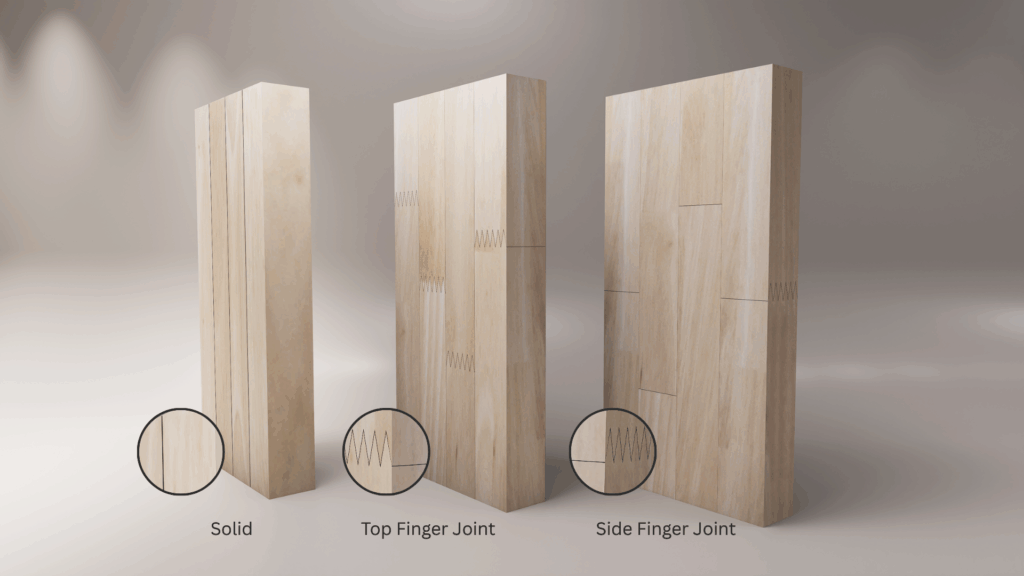

What Is a Finger Joint Board?

Finger joint board is a precision-engineered wood panel made by joining short pieces of solid wood with interlocking “fingers,” creating a stronger, more stable furniture wood solution. Whether used for furniture wood manufacturing, interior paneling, or custom joinery, laminated wood offers the ideal balance of durability, cost-efficiency, and sustainable material use.

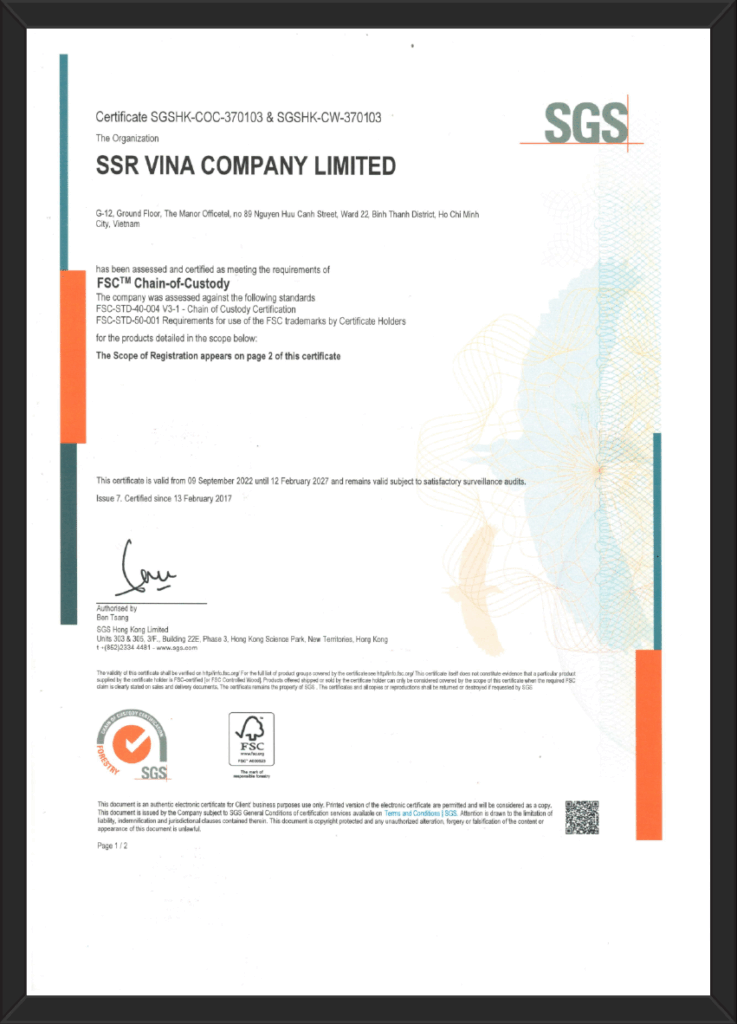

Sustainable by Design

Choosing a finger joint board means supporting responsible forestry and waste reduction. By repurposing smaller solid wood segments into high-quality wood boards, SSR VINA- wood manufacturer minimize raw material waste and reduce the need for harvesting large-diameter logs. This makes finger joint-board a smarter, more eco-friendly choice for furniture wood and architectural applications, meeting both environmental standards and global market demands.

Available Dimensions

Our finger joint laminated boards are high-quality wooden panels made from premium furniture wood, offered in standard sizes: thicknesses of 12, 15, 18, 24, and 30 mm, with a width of 1220 mm and length of 2440 mm (48″ × 96″). Ideal for furniture, cabinetry, and interior projects, they ensure easy handling, cutting, and installation. As a trusted B2B manufacturer and global supplier, we provide consistent quality, competitive pricing, and custom options in sizes, thicknesses, and finishes to match your specific requirements.

The Smarter Choice for Furniture Grade Panels

Solid wood brings timeless beauty and durability, making it a premium choice for fine furniture. For projects requiring more size options, better material efficiency, and enhanced stability, Top Finger Joint and Side Finger Joint laminated boards stand out. These engineered panels join smaller, selected wood segments into strong, uniform wooden planks, reducing waste while maintaining a natural look. With consistent quality, versatile applications, and sustainable sourcing, finger joint boards offer a modern, cost-effective edge—while solid wood remains the go-to for classic elegance.

SSR VINA Finger Joint Wood Board Benefits

Uniform Dimensions

Eco-friendly

Consistent Quality

Easy to work with

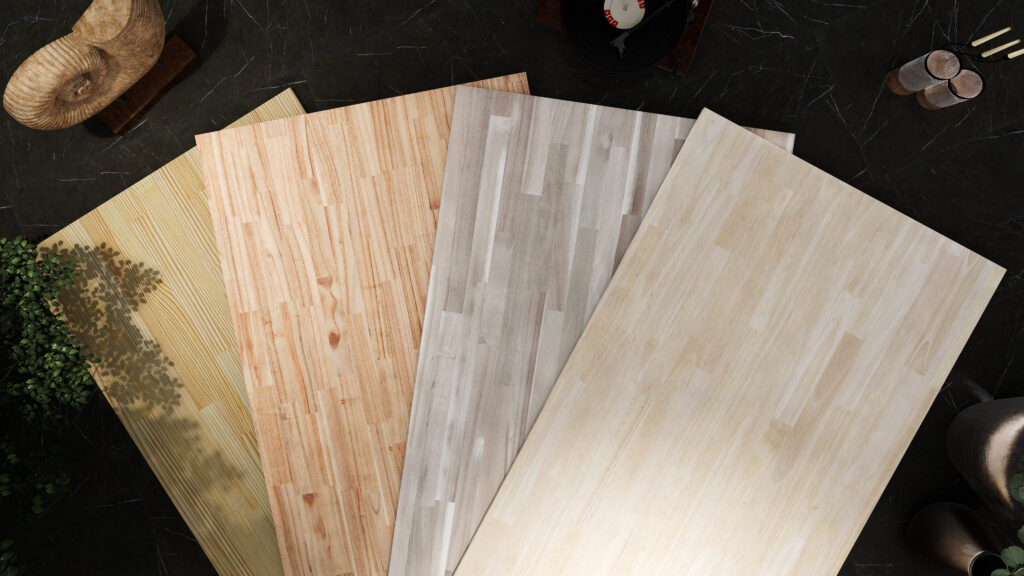

SSR VINA Finger Joint Wood Board Products

About the wood

- Color: Light beige to pale yellow

- Texture: Uniform grain, smooth finish

- Key Features: Eco-friendly (from reclaimed plantation trees), stable and easy to process

Pine

About the wood

- Color: Pale yellow with visible growth rings

- Texture: Soft, with straight grain

- Key Features: Lightweight, easy to machine, cost-effective

Melia

About the wood

- Color: Reddish-pink to medium brown ring

- Texture: Coarse grain, often with knots

- Key Features: Affordable, lightweight, easy to work with

Why SSR VINA?

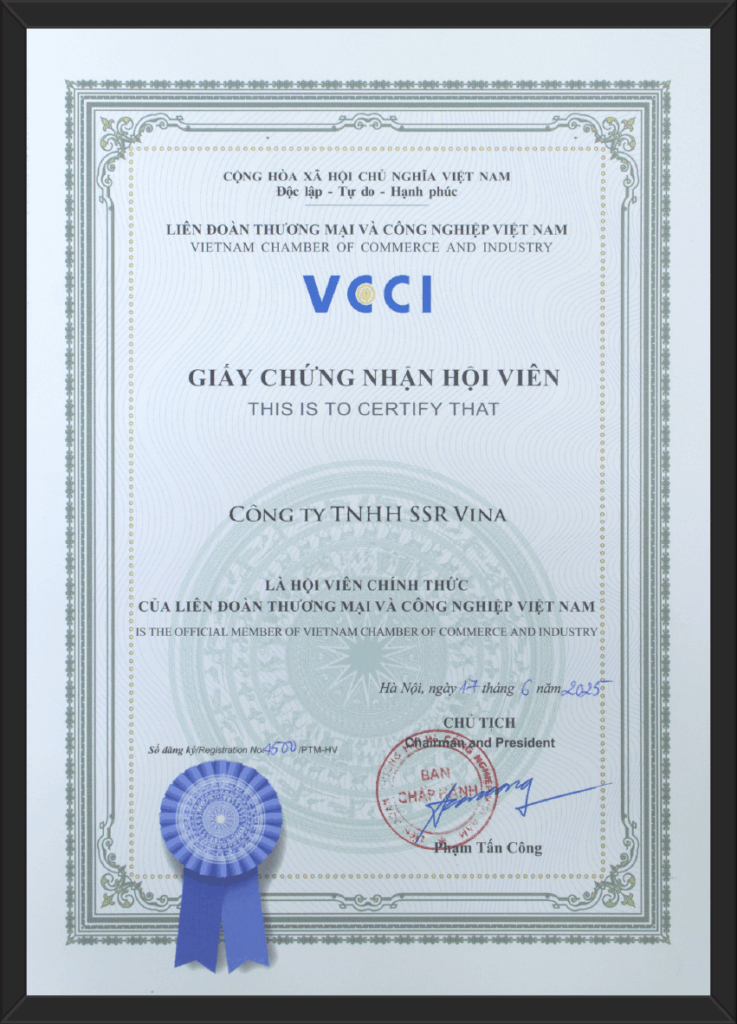

Certificates

FSC

Chain of Custody

Quality Management

ISO 9001: 2015

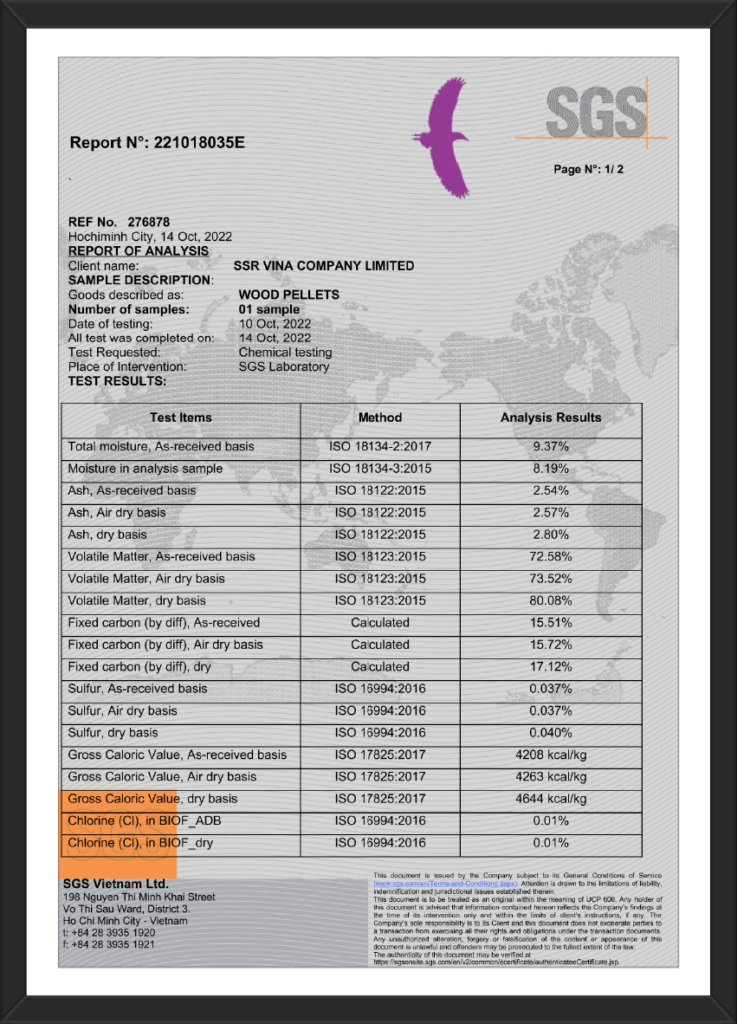

SGS Standard

VCCI Member

Quality Inspection

Every product undergoes a strict quality inspection process before shipment. Our team carefully checks dimensions, surface finish, moisture content, and structural integrity to ensure each piece meets international standards. From raw material selection to final packaging, we maintain consistent quality control, guaranteeing reliability and satisfaction for our B2B partners.

Moisture Check

Dimensions Check

Finger Joint Check

Machine Calibration

OEM & ODM Manufacturing Capabilities

At SSR Vina, we turn your ideas into ready-to-sell finger joint boards and furniture wood panels. Whether you need your own brand, custom sizes, special finishes, or tailored packaging, our OEM and ODM services make it happen.

With modern machinery, skilled craftsmen, and strict quality control, we deliver consistent quality, competitive prices, and on-time shipments to customers in the US, Japan, Korea, and the EU.

Factory Centers

Our factories follow strict 5S and lean management principles, with quality control at every stage, regular machinery maintenance, and well-organized production zones from raw material storage to final inspection, ensuring precision, consistency, and on-time delivery for global markets

Phu Tho – Vietnam

Gia Lai – Vietnam

Ho Chi Minh – Vietnam

Surat Thani – Thailand

By The Numbers

Our Production Process

Looking for a B2B

Finger Joint Board Supplier?

Our wood panel specialists are ready to help with your project needs